Hygienic CleanSheet walls and ceilings

CleanSheet

PolySto CleanSheet (Hygienic FRP-sheet) is a glass fiber reinforced composite polyester sheet, ideal to build and protect structures that require additional resistance to prevent deformation and corrosion.

CleanSheet is non-corrosive, strong, lightweight, maintenance free, and can be installed efficiently and economically.

CleanSheet is the base of our wide range of composed (laminated) panels such as RamPanel, RenoPanel, InsuPanel, HygiWall and HygiCeiling.

Why is CleanSheet the best solution for you?

Possible problems with hygienic walls & ceilings.

Hygienic walls & ceilings in a food production facility are challenged every day by heavy wear-and-tear activities, substances and environmental conditions. Mechanical impacts to these surfaces, cleaning products, salt, humidity, blood, acids, starch, and dairy residues are just a few of examples of items that can rapidly deteriorate the condition of hygienic walls & ceilings.

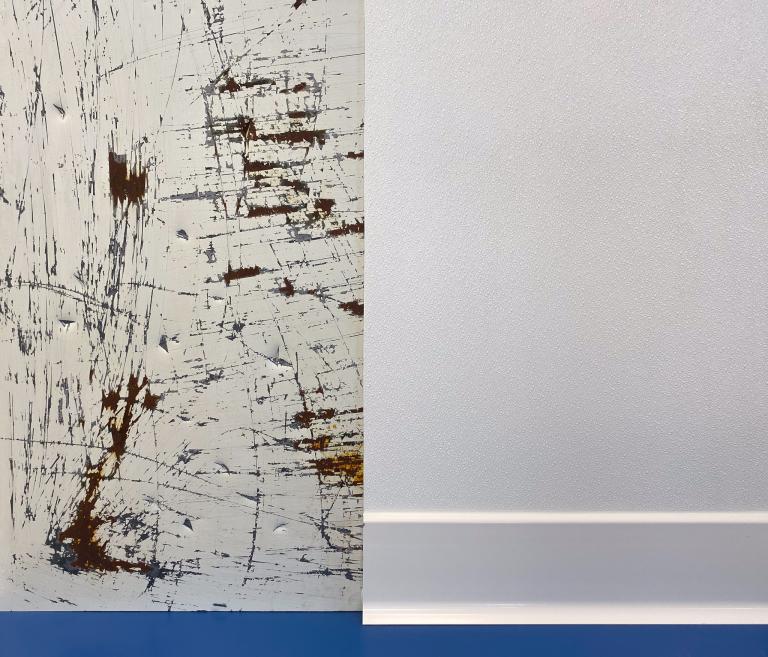

Walls composed of tiles, stainless steel or aluminium sandwich panels offer great challenges in creating a hygienic, food safe environment. Over the years the surface of tiled walls can be damaged due to physical impacts with moveable equipment and mechanical cleaning processes. Metal sandwich panels are protected by a very thin layer of a few microns of paint and/or plastic.

When used in intensive food production areas, these panels suffer from corrosion problems and the thin layer of paint coating will start to peel off. In addition, the metal surface of a sandwich panel is very thin and therefore weak against physical or mechanical impacts. The silicone joint (if any) between the sandwich panels can cause problems after a few years as they cannot withstand high pressure cleaning or industrial cleaning agents. Repainting a sandwich panel is not a good option, not only because it requires production to be stopped while repainting, but because it is labour intensive with little return. Essentially, newly applied paint on the sandwich panel is highly likely to peel or chip off since good adhesion of the new coat is unlikely. Paint chips contaminating the production line is a clear food safety risk that must be avoided.

PolySto CleanSheet solutions for hygienic walls & ceilings.

CleanSheet is the ideal solution for hygienic walls & ceilings in a food production facility. CleanSheet is extremely strong, durable, non-corrosive and easy to clean. The surface is either smooth or embossed.

Applying cleaning foam on embossed CleanSheet surfaces result in a more efficient cleaning process saving on foam consumption (up to 25% less foam consumption and 25-30% less residues of bacteria after cleaning). Moreover, the embossed surface has filth-repellent characteristics.

The smooth CleanSheet surface is a better choice when used in areas that generate a high volume of dust particles, such as milk powder, bakery ingredients, powdered nutrition ingredients and pharmaceutical production facilities.

Emissions in the interior

CleanSheet obtained the Afsset (A+) certificate. Afsset is a European certificate used for emission regulations of organic volatile substances in the interior. A+ is the best category meaning very low to zero emissions.

CleanSheet helps ensure minimal impact on your indoor environment. All CleanSheet solutions are compliant with the Greenguard certification!